From Director’s Desk

On the onset of new crushing season 2017- 18, I wish all the stakeholders a very prosperous and smooth crushing season. With stable and comfortable sugar prices along with estimated sugar production of around 24 mi llion tonnes during the crushing season 2017 - 18, the su gar factories are expected to remain comfortable even with somewhat escalation in FRP and possible increase in SAP’s. As per the reports available, Uttar Pradesh is again going to dominate with sugar p roduction estimated to be around 10 million tonnes during 2017 - 18 due to rise in area under sugarcane cultivation and expected rise in productivity. However, environmental issues are going to be of prime importance with stringent controls being exercised b y the CPCB to maintain quality and quantity of effluent discharge from the sugar factories situated particularly in the Ganga Basin. Off course, molasses based distilleries are no exception.

However, sugar factories need not to be complacent and any swing in sugar prices in future may put them on the back foot. Diversification is important for sustainability and considering this the institute has taken up R&D work on production of Bio - CNG from Press Mud and Bio - detergent from sugarcane bagasse. Many more studies are in the pipeline and I look forward towards better institute - industry interaction carrying out collaborative work on various areas of interest viz. developing cost effective technologies for waste water treatment, particularly, treatment of spra y pond overflows and utilization of by - products in an innovative manner. It seems essential of increase revenue earnings through better by - product utilization which thus will act as shock absorber to some extent during downward trend in the sugar prices.

Our Research Areas:

The Institute is actively involved in the collaborative endeavors with the sugar and allied industries for developing innovative techniques and technologies for improving the overall profitability of the sugar industry.

<>Research:

The Institute during the period took up R&D work on the following:

1. Isolation and purification of yeast strains from saccharine materials and their performance for fermentative production of alcohol- The yeast strain isolated from spoiled sugar cane juice produced best results when diluted molasses was fermented by this strain with a fermentation value of 91.7% and ethanol yield of 218 l/ton. The yeast isolated from rotten grapes also produced good results. Three selected strains were tested for their efficiency on molasses medium. The experiments are being repeated to validate the results.

2. Bio- CNG from Press Mud- With an aim to utilize the press mud for production of BioCNG,different combinations of press mud, farm yard manure and spent wash have been tried. Overall gas formation patterns in ten selected treatments were studied with the help of gas analyzer, out of which five showed best results. Physico-chemical analysis of the slurry of best combinations is in progress to ascertain its possible use as bio-manure.

3. Studies on clarification of cane juice with bagasse derived bio-char- The study has been taken up with an aim to utilize the bagasse fly ash in combination with bio char to check its de-colorization efficiency on cane juice, and other sugar liquors. In order to implement the bagasse fly ash as an adsorbent to clarify/de-colorize the sugarcane juice, the analysis of input parameters such as pol, brix, purity, conductivity ash, colour, turbidity, starch and dextran of sugarcane juice to be treated is under process for exploring further possible use.

4. Mushroom Cultivation from different lignocellulosic substrates- To explore possibilities of utilization of bagasse as substrate for mushroom cultivation, studies have been taken up. The studies shall be extended further using other lignocellulosic substrates. The study has been aimed at utilizing bagasse, a lignocellulosic material, as a cheap source for growing fungal cultures instead of using conventional Potato Dextrose Agar medium etc.

5. Studies on synthesis of glycosidic surfactants using by-product resources of sugar industry- Preliminary studies have been completed and a bio-detergent has been successfully produced on the laboratory scale. Studies have been taken up further so as to enhance the yield of bagasse derived polypentosides based surfactant along with reducing the purification steps involved thereof. An experiment has been performed on 10 gm scale to synthesize the glycosidic surfactant. The purification and characterization of the product is under evaluation. Patent application on this topic has been filed.

7. Settling test using Lamella Clarifier - The literature survey has been done and a Laboratory model for the experiment is under construction for the actual assessment of mud removal & quality parameters of clear juice. Lab trials on this new design of clarifier will be carried out during next crushing season.

RESEARCH PAPERS/ POSTER / PRESENTED / PUBLISHED/ SENT FOR PUBLICATION:

1. " Sugar Warehouse Automation: Minimize Loss & Maximize Output” by Shri Brajesh Singh, published in 75th STAI Annual Convention proceeding held on 03-05th August 2017 at Kochi, Kerala.

2.“Raw-Refined Sugar Production-Opportunities & Challenges” by Anushka Agarwal & Narendra Mohan presented during all India seminar jointly organized by NSI and S. Nijalingappa Sugar Institute on 28th August 2017 at Belagavi, Karnataka.

3. “Carbonation & Phosphatation Refinery: A Practical Approach” by Narendra Mohan and Mahendra Yadav presented during all India seminar jointly organized by NSI and S. Nijalingappa Sugar Institute on 28th August 2017 at Belagavi, Karnataka.

4. “Organic Sugar: A Real opportunity” by Ashutosh Bajpai and Vivek Pratap Singh presented during all India seminar jointly organized by NSI and S. Nijalingappa Sugar Institute on 28th August 2017 at Belagavi, Karnataka.

5. “Quality of Indian Sugars: Opportunities & Challenges” by Narendra Mohan & Anushka Agarwal presented during the technical session in one day National conference AMIFOST-2017 organized by Amity University on 26th September,2017 at Noida U.P.

6. “Indian sugar industry: A way forward” by Narendra Mohan, V P Srivastava, Shikha Singh & Anushka Agarwal presented during Sugar Tech- 2017 organized jointly by NSI-CII on 20th September, 2017 at Lucknow.

OUR PROVISIONS:

BUREAU OF SUGAR STANDARDS:

The Institute on behalf of Bureau of Indian Standards prepares and issues Sugar Standard Grades to the entire Sugar Industry of the country for every sugar season. These Sugar Standard Grades are issued to facilitate quality control and to protect the interest of the common consumers. On the basis of these grades, sugar factories mark their produce accordingly.

On the basis of the approved Standards, Bureau of Sugar Standards Grades distribution will be commencing from 3rd October, 2017

Price schedule for the sugar season 2017-18:

| 1 | Sugar Standard Grades to be issued | L-31, L-30, M31, M-30, S-31,S-30 & SS31 |

| 2 | Set of New Sugar Standard Grades containing 7 grades +3 empty glass bottles + 3 Velvet Cork in packing case | Rs.10000/= each set |

| 3 | Single Sugar Standard Grade | Rs.1260/= each |

| 4 | Empty Sugar Standard Glass Bottle | Rs.200/= each |

| 5 | Packing case | Rs.430/= each |

| 6 | Velvet Cork | Rs.50/= each |

| 7 | Postal expenses, forwarding charges, if any | Extra on actual basis |

| 8 | Demand Draft to be sent | In favour of Director, National Sugar Institute, payable at Kanpur |

| 9 | Delivery of Sugar Standard Grades | Monday to Friday (10.00 AM to 5.00 PM) |

| 10 | Taxes | GST extra as applicable |

SEMINAR/WORKSHOP/TRAINING PROGRAMMES:

TRAINING PROGRAMME ORGANIZED:

1. Four weeks Customized Training Programme for the Graduate Engineer Trainees of M/s EID Parry (India) Ltd., Chennai was conducted at the Institute. Theoretical as well as practical training was imparted to the trainees on various techniques of milling, boiler, co-generation, juice extraction, clarification, evaporation and crystallization etc. They were also exposed on various techniques of effluent/waste water treatment and on water conservation.

2. First phase of five days training programme on "ETP Operation & Techniques of water/effluent Analysis” was conducted from 4-8th September, 2017. Dr. S. Soloman, Vice Chancellor, CSA University of Agri. & Tech., Kanpur inaugurated the function. The participants were educated on recent guidelines of CPCB and on various innovative techniques of effluent / waste water treatment and its analysis.

3. IInd phase of five days training programme on "ETP Operation & Techniques for water/effluent Analysis" was conducted from 18-22nd September, 2017. Shri Suresh Kumar Singh, Managing Director, UP Co-operative Sugar Factories Federation Ltd., Lucknow inaugurated the programme and highlighted the importance of the subject matter. Various technology providers and other experts made their presentation during the training programme. Theoretical as well as practical aspects of treating different waste waters for their possible re-use were made clear to the participants.

SEMINARS/CONFERENCES:

1. One day all India seminar was jointly organized by NSI and SNSI on “Advance Technologies for Raw-Refined and Specialty Sugar Production" on 28th August, 2017 at Belagavi, Karnataka. The seminar was attended by large no. of delegates from Karnataka, Maharashtra and Tamil Nadu.

2. Shri Narendra Mohan, Director attended Annual Convention of DSTA at Belgavi and presented a paper on "Determination of Sugar Quality keeping in view market requirement”.

3. Shri Narendra Mohan, Director inaugurated International Symposium and Expo at Kolhapur where he was also Conferred with "Bharatiya Sugar Award” for overall outstanding performance as “Institutional Head-National Level". Dr. Vishnu Prabhakar Srivastava, Asstt. Professor, Organic Chemistry was conferred with "Bharatiya Sugar Award” for “Best overall performance in R&D".

4. Shri Narendra Mohan, along with Shri D. Swain, Prof. Sugar Engineering, Shri J.P. Srivastava, Chief Design Engineer, Dr. A. Bajpai, Prof. Sugar Technology and Dr. V.P. Srivastava, Assistant Prof., Organic Chemistry attended 75th Annual Convention of STAI from 3rd to 5th August, 2017at Kochi.

While Shri Narendra Mohan, Director was conferred with “Industry Excellence Award”, Shri J.P. Srivastava got ISGEC Gold Medal-Engineering for Excellence. Four nos. research papers were also presented by the institute experts on this occasion.

5. Shri Narendra Mohan addressed the "Technical Conclave" organized by M/s Dhampur Sugar Group” on 12th August, 2017 at New Delhi where he delivered a lecture on “Recent advancements in processing”.

6. Sugar Tech -2017 was jointly organized by NSI and CII on 20th September, 2017 at Lucknow. Hon’ble Minister of Sugarcane Development and Industries, Shri Suresh Rana and Principle Secretary (Sugar), Government of U.P also graced the occasion. Various issues concerning sustainability, environment & modernization of sugar industry were discussed during the seminar. A paper entitled “Indian sugar industry - A way forward” was also presented by the institute.

TRAINING PROGRAMME FOR IAS/PCS PROBATIONERS:

1. Two batches of PCS Probationers visited Institute on 30th August, and 1st September, 2017 to participate in interactive sessions on “Issues related to sugarcane production, milling, marketing, and management

2. IAS probationers took part in the training programme conducted at the institute on 5th September, 2017 on the topic “Issues related to Sugar and Ethanol Production for sustainability of the Sugar Industry”.

EXTENSION LECTURES:

1. Shri Manoj Kumar Upreti, General Manager (Production), Balrampur Chini Mills Ltd. delivered a lecture on “Innovative techniques in Standalone Refineries in different part of world to improve their Sustainability” on 1st August, 2017 at the Institute.

2. Shri Rajeev Gupta, General Manager-Marketing, M/s Jindal Stainless Ltd delivered a Lecture on “Causes of Corrosion and use of Stainless Steels” in sugar industry on 18th August, 2017 at the Institute.

3. Dr. (Mrs.) Priyanka Singh, Scientific Officer, U.P. Council of Sugarcane Research, Shahjahanpur delivered a lecture on "Sugarcane Management for higher Sugar Recovery" at the institute.

4. Shri Jivan Jyoti Bhagat, Director, STM Projects, New Delhi delivered a very informative lecture for the benefit of staff and students on “Water Management and Laboratory Practices”. He also took keen interest in the institute activities.

5. Shri S.K. Bhojraj, a renowned consultant and President (Sugar), Crystal Engineers, Pune delivered a very informative and interactive lecture for the benefit of staff and students on “Evaporator Configuration for Higher Steam Economy”.

6. Mr. Rajesh Singh, Sr. Manager (QC), Triveni Engineering & Industries Ltd., delivered a lecture on “DLP & GMP for manufacturing of Plantation white & refined sugar” covering various aspects of laboratory analysis.

7. Dr. Protibha Nath Banerjee, Scientist, University of Dodoma, Tanzania, delivered a lecture on “By- product Utilization in a Bio refinery Concept: Non- Cellulosic Heteropolysaccharide from Sugarcane Bagasse”.

INDEPENDENCE DAY:

On 71th Independence Day, the Director, hoisted the National Flag at the Institute and addressed the staff, students and faculty members. He called upon the students to follow the mantra of ADD i.e. Attitude, Discipline and Dedication for achieving success in life. The prizes were also distributed to the winners of various competitions organized during the Swachhta Pakhwada

NEW INDIA PLEDGE:

"New India Pledge" was administered to the staff and students of the institute in connection with 75th Year of "Quit India Movement" and 70th year of Independence.

ORIENTATION PROGRAMME:

An Orientation programme was organized for the fresh batch of students admitted during the academic session 2017-18 in various courses conducted by the Institute. Shri Narendra Mohan, Director addressed the students and stressed upon the need for maintaining disciplines in all sphere of life. Hostel Warden’s and Education In-charge also briefed the newcomers about the various rules and regulations etc. of the institute.

FRESHER’S PARTY:

The students of various courses organized a function to celebrate the Fresher’s Party on 19th August, 2017. Many activities viz. singing, dance and drama etc. were performed by the senior students. After various rounds to test the overall personality, Mr. Amarnath Singh, (Instrumentation & Automation, Ist yr) & NSI Ms. Anshu Singh, (Sugar Tech. Ist yr) were chosen as Mr. and Ms. NSI respectively.

TEACHERS DAY:

The students of various courses organized a function to celebrate the Teacher’s Day on 5th September 2017. On the occasion of teacher’s day, Shri Narendra Mohan, Director, while remembering the contribution of Dr. S. Radha Krishnan, Ex-Vice President, delivered a lecture highlighting the role of teacher in character and career building of students.

TREE PLANTATION:

Institute continued its efforts for creating awareness about environment protection and in the process a programme on "Tree Plantation" was organized at the institute jointly with Juhari Devi PG Girls College, Kanpur on 24th August, 2017.

VISHWAKARMA POOJA:

“Vishwakarma Pooja” was organized in the Experimental Sugar Factory, Instrumentation Division & Agricultural Farm on 17th September, 2017. Large no. of staff members and students participated in the function.

हिंदी पखवाड़ा:

सरकारी कामकाज में राजभाषा के रुप में हिन्दी के प्रति जागरुकिा लाने तथा उसके उत्तरोतर विकास हेतु संस्थान में दिनक 01 सितम्बर से 15 सितम्बर 2017 तक हिन्दी पखवाड़ा: मनाया गया। हिंदी पखवाडा के दौरान आयोजित विविध प्रतियोगिता में विजेता स्टाफ़ एव छात्रों को पुरस्कार से नवाजा गया। हिन्दी पखबाडे का उद्घाटन डॉ0 अरविन्द सिंह , विभागाध्यक्ष, क्राइस्ट चर्च महाविदयालिय, कानपुर ने किया। हिन्दी पखबाडे के दौरान आयोजित विभिन्न पप्रतियोगिता निम्न संस्थान कर्मी प्रथम रहे ।

| हिन्दी टिप्पण आलेखन प्रतियोगिता | श्री सन्तोष कुमार त्रिपाठी |

| हिन्दी निबन्ध प्रतियोगिता | श्री दयाशंकर मिश्रा |

| हिन्दी निबन्ध प्रतियोगिता( केवल एम.टी. एस. कर्मचारीयों के लिये ) | श्री बाल किशन मीणा |

| हिन्दी टंकण प्रतियोगिता | श्री रामकान्त |

| हिन्दी व्याख्यान प्रतियोगिता | श्री दयाशंकर मिश्रा |

| हिन्दी प्रचार-प्रसार प्रतियोगिता | श्री एस.के . त्रिवेदी |

| हिन्दी सामान्य ज्ञान प्रशनोत्री प्रतियोगिता | श्री रामकान्त |

| हिन्दी सामान्य ज्ञान प्रशनोत्री प्रतियोगिता ( केवल एम.टी. एस. कर्मचारीयों के लिये ) | श्री धर्मेन्द्र कुमार शाह |

राजभाषा पारितोषिक:

राजभाषा पारितोषिक योजना के अंतर्गत वर्ष 2016-17 के दौरान राजभाषा नीति के “क” एव “ख” क्षेत्र के अंतर्गत संस्थान को उत्कृष्ट कार्यान्वन हेतु तृतीय स्थान प्राप्त हुआ

SCIENTIFIC SOCIETY ANNUAL FUNCTION:

The inaugural function of the Scientific Society under the Council of Student’s Activities was organized on 25th September, 2017 at National Sugar Institute, Kanpur. The function was graced by Shri S. K. Bhojraj, one of the most eminent and versatile Sugar Technologist. Prizes were also given to the winners of various competitions.

ANNUAL SPORTS:

Annual Sports under the auspices of Council of Students Activities were organized from 11 to 23rd September, 2017 at the Institute. Besides team events e.g. Inter Class Cricket & Volleyball, individual events for Chess, Table Tennis, Badminton and Athletics etc. were also organized. Boys & Girls studying in the various courses actively participated in games and sports.

Winners (Boys) of indoor and outdoor games are as under:

| Event | Winner |

|---|---|

| Badminton (Single) | Dev Prakash Gupta-DIFAT-1st Yr |

| Carom (single) | Abhishek-SE-2nd Yr. |

| Carom (Double) | Nikunj & Akhilesh-DIIPA |

| Table Tennis (single) | Anand Hari-SE-2nd Yr. |

| Table Tennis | Saignik Ganguli & Arnab Nandi-DIFAT-2 |

| Badminton(Doubles) | Shobhit Taygi, Ansuman Singh -SE-2 |

| Chess | Piyush-DIFAT |

| Cricket | Sugar Technology 3rd Year. |

| Javellin Throw | Gaurav Yadav – ST-2nd Yr |

| Discus Throw | Shobhit Taygi-SE-2nd Yr |

| Athletics(100&200M) | Kuldeep Shukla – ST-1st Yr. |

| Volleyball | Sugar Engineering Final Year. |

Winners (Girls) of indoor and outdoor games are as under:

| Event | Winner |

|---|---|

| Badminton (Single) | Amrita Yadav - CCQC |

| Chess | Akanksha Mishra -Research Scholar |

| Table Tennis | Akanksha Mishra -Research Scholar |

| Athletics (100M) | Sangeeta Verma-DIFAT-1st Yr. |

| Javelin Throw | Sangeeta Verma-DIFAT-1st Yr |

| Carom | Ranjana Kashyap-ST-2nd Yr |

SWACHHTA PAKHWADA:

Swachhta Pakhwada was observed from 15th to 02nd October, 2017 at the Institute, as per schedule. Various activities like tree plantation, cleaning activities in & around surroundings, inspiring the primary school students about the importance of cleaning, conducting a drawing competition on Swachhta in a nearby primary school were carried out. An essay/poem competition and Blood Donation Camp was also organized at the institute.

A “Nukkad Natak” was also organized on this occasion to create awarness about importance of personel hygiene & its affect on human health.

रक्तदान शिविर:

संस्थान में दिनाकं 28 सितम्बर 2017 ,को मायांजलि चैरिटेबल ब्लड बैंक तथा रोटरी क्लब ,कानपरु के सहयोग से रक्तदान शिविर का आयोजन किया गया।इसमें संस्थान के अधिकारियों ,कर्मचारीयों एव छात्र-छात्राओं द्वारा रक्तदान किया गया।

PREPARATION & SALE OF SUGAR STANDARDS GRADES:

Meeting of the Committee of Experts constituted by the Govt. of India under the Chairmanship of Director, National Sugar Institute for approval of Sugar Standards Grades for the season 2017-18 was held on 28th September, 2017.

Meeting was attended by representatives from Bureau of Indian Standards, NFCSF, STAI, Indian Institute of Sugarcane Research and Indian Institute of Toxicological Research, Lucknow. The distribution of Standards will commence from 3rd October, 2017. The details are available on institute website www.nsi.gov.in.

PLACEMENTS:

Campus interviews were conducted by the following sugar factories and other companies to recruit students of various courses.

- M/s DSCL Sugars Ltd., UP.

- M/s Dhampur Sugar Mills Ltd., UP.

- M/s Avadh Sugar & Energy Pvt. Ltd., UP.

- M/s Dalmia Bharat Sugar & Industries Ltd.,

- M/s Balrampur Chini Mills Ltd., UP.

- M/s Uttam Sugar Mills Ltd., UP.

- M/s Wave Industries Pvt. Ltd. UP.

- M/s ISGEC Ltd., Noida, U.P.

- M/s K.M. Sugar Mills Ltd. Faizabad, UP.

- M/s LEHUI India Ltd., Vadodara, Gujarat

- M/s Daurala Sugar Works Ltd., Meerut,

- M/s Mawana Sugar Works Ltd., Meerut,

- M/s Catalyst Ltd., Guru Gram, Haryana

- M/s Spray Engineering Devices Ltd. Chandigarh.

Further interviews have been confirmed by M/s Global Cane Sugar, New Delhi and M/s Parwati Sweetners Ltd., Gwalior, Madhya Pradesh.

OUR ADVISORY:

Besides conducting teaching and training programmes, carrying out research in relevant field, another main function of the institute is:

1. To function as a “Think-tank” to sugar and allied industry for proposing modernization and trouble free functioning of the process on advisory basis / through Extension Services.

2. To formulate strategies and promotes measures for expansion of capacities, energy conservation, co-product utilization etc. for sugar and allied industries.

3. To assist Govt. of India through technical contribution in policy formulation and control of Sugar Industry.

CONSULTANCY SERVICES:

During the period July to September, 2017 consultancy services were provided to the following:

| 1. | M/s Balrampur Chini Mills Ltd., Unit-Babhnan(Sugar Division) Distt- Gonda, U.P |

| 2. | M/s Tulsipur Sugar Company, Unit- Balrampur Chini Mills Ltd., Distt- Balrampur, UP. |

| 3. | M/s Balrampur Chini Mills Ltd., Unit- Balrampur, Distt- Balrampur, UP. |

| 4. | M/s Dewan Sugar Ltd., Kanth Road Agwanpur, Distt-Moradabad, U.P. |

| 5. | M/s Sonipat Coop. Sugar Mills Ltd., Sonipat, Haryana |

| 6. | M/s DSCL Sugar, Unit-Hariawan, Distt-Hardoi, U.P |

| 7. | M/s Triveni Engineering & Industries Ltd., Unit-Chandanpur, Distt-Amroha, U.P |

| 8. | M/s Dalmia Bharat Chini Mills, Unit-Ramgarh, Distt-Sitapur, U.P. |

| 9. | M/s Triveni Engineering & Industries Ltd., Unit-Milak Narayanpur, Distt-Rampur, U.P. |

| 10. | M/s Upper Doab Sugar Mills, Shamli, Distt-Shamli, U.P |

| 11. | M/s Tikaula Sugar Mills, Ltd., Muzaffarnagar, U.P. |

| 12. | M/s The Bazpur Co-op Sugar factory Ltd., Bazpur, Uttarakhand. |

| 13. | M/s The Kisan Sahkari Chini Mills Ltd., Nadehi, U.S. Nagar, Uttarakhand. |

| 14. | M/s Kichha Sugar Co. Ltd., Kichha, U.S. Nagar, Uttarakhand. |

| 15. | M/s Daurala Sugar Works, Daurala, Distt-Meerut, U.P |

| 16. | M/s Uttar Pradesh Rajya Chini Nigam Ltd., Unit-Mohiuddinpur, Distt-Meerut, U.P. |

| 17. | M/s Triveni Engineering & Industries Ltd., Unit-Sabitgarh, Distt-Bulandshahar, U.P |

| 18. | M/s Dhampur Sugar Mills, Ltd., Unit-Dhampur, Distt-Bijnor, U.P. |

| 19. | M/s DSM Sugar Unit-Asmoli, Distt-Muradabad, U.P |

| 20. | M/s Sasa Musa Sugar Works Pvt. Ltd., Sasa Musa, Distt-Gopalganj, Bihar |

| 21. | M/s Dwarikesh Sugar Industries Ltd., Unit-Afjalpur, Distt-Bijnor, U.P. |

| 22. | M/s E.I.D. Parry (India) Ltd., Dare, Chennai, TamilNadu. |

| 23. | M/s Triveni Engineering & Industries Ltd., Unit-Khatauli, Muzaffarnagar, U.P. |

| 24. | M/s Triveni Engineering & Industries Ltd., Unit-Sabitgarh, Bulandshahr, U.P. |

| 25. | M/s Dwarikesh Sugar Industries Ltd., Unit-Dwarikesh Dham, Faridkot Bareilly, U.P. |

| 26. | M/s D.S.M. Sugar Mills Ltd., Unit-Rajpura, Sambhal, U.P. |

| 27. | M/s D.S.M. Sugar Mills Ltd., Unit- Meerganj, Bareilly, U.P. |

| 28. | M/s Saf Yeast Company Pvt. Ltd., Hardoi U.P. |

| 29. | M/s Uttam Sugar Mills Ltd., Unit- Libberheri, Haridwar, Uttarakhand |

| 30. | M/s Uttam Sugar Mills Ltd., Unit- Barkatpur, Haridwar, Uttarakhand |

| 31. | M/s Uttam Sugar Mills Ltd., Unit - Khaikheri, Haridwar, Uttarakhand. |

| 32. | M/s Uttam Sugar Mills Ltd., Unit- Shermau, Haridwar, Uttarakhand |

| 33. | M/s Triveni Engineering & Industries Ltd., Unit - Milak Narayanpur, Rampur, U.P. |

| 34. | M/s Triveni Engineering & Industries Ltd., Unit- Rani Nagal, Moradabad, U.P. |

| 35. | M/s Daurala Sugar Works, Daurala, Meerut, U.P |

| 36. | M/s Dalmia Bharat Sugar & Industries Ltd., Unit-Jawaharpur, Sitapur, U.P. |

| 37. | M/s Mawana Sugar Works, Mawana, Distt- Meerut, U.P |

| 38. | M/s Gobind Sugar Mills Ltd., Aria Estate, Distt- Kheri, U.P. |

| 39. | M/s Seksaria Biswan Sugar Factory Ltd., Biswan, Distt- Sitapur, U.P |

| 40. | M/s L.H. Sugar Factory & Oil Mills Pvt. Ltd., Saukara, Distt- Pilibhit, U.P. |

| 41. | M/s PBS Food (Sugar) Pvt. Ltd., Chandpur, Bijnor |

| 42. | M/s Wave Industries Pvt. Ltd., Dhanaura, Distt- Amroha, U.P |

| 43. | M/s Wave Industries Pvt. Ltd., Distt- Bijnor, U.P. |

| 44. | M/s Kanoria Sugar & Gen. Manufacturing Company Ltd., Captainganj, DisttKushinagar,U.P |

| 45. | M/s Chadha Sugar & Industries Pvt. Ltd., Distt- Gurdaspur, Punjab |

| 46. | M/s Rajasthan State Ganganagar Sugar Mills Ltd., Sri Ganganagar, Rajasthan. |

| 47. | M/s Bajaj Hindustan Sugar Ltd., Rudhauli Distt- Basti, U.P. |

| 48. | M/s Bajaj Hindustan Sugar Ltd., Utraula, Distt- Balrampur, U.P. |

| 49. | M/s Bajaj Hindustan Sugar Ltd., Pratapur, Distt- Deoria, U.P. |

| 50. | M/s Bajaj Hindustan Sugar Ltd., Kundarki, Distt- Gonda, U.P. |

| 51. | M/s Bajaj Hindustan Sugar Ltd., Golagokarannath, Distt- Lakhimpur Kheri, U.P. |

| 52. | M/s Bajaj Hindustan Sugar Ltd., Palia Kalan, Distt- Lakhimpur Kheri, U.P. |

| 53. | M/s Bajaj Hindustan Sugar Ltd., Khambarkhera, Distt- Lakhimpur Kheri, U.P. |

| 54. | M/s Bajaj Hindustan Sugar Ltd., Berkhera Kalan, Distt- Pilibhit, U.P |

| 55. | M/s Bajaj Hindustan Sugar Ltd., Maqsoodapur, Distt- Shahjahanpur, U.P. |

| 56. | M/s Bajaj Hindustan Sugar Ltd., Thanabhawan, Distt- Shamili, U.P. |

| 57. | M/s Bajaj Hindustan Sugar Ltd., Budhana, Distt- Muzaffarnagar, U.P. |

| 58. | M/s Bajaj Hindustan Sugar Ltd., Bilai, Distt- Bijnor, U.P. |

| 59. | M/s Bajaj Hindustan Sugar Ltd., Distt- kinauni, Meerut, U.P. |

| 60. | . M/s Bajaj Hindustan Sugar Ltd., Gangnauli, Distt- Saharanpur, U.P. |

| 61. | M/s Wave Industries & Pvt. Ltd., Saharanpur, U.P |

| 62. | M/s Wave Industries & Pvt. Ltd., Unit-Bulandshahar, U.P |

| 63. | M/s Simbhauli Sugar Ltd., Unit- Brijnathpur, Distt- Hapur, U.P. |

| 64. | M/s Simbhauli Sugars Ltd., Unit- Simbhauli Sugar Simbhauli, Distt- Hapur. |

| 65. | M/s Oswal Overseas Ltd., Nawabganj, Distt- Bareilly, U.P |

| 66. | M/s DSM Sugar Meerganj Unit of Dhampur Sugar Mills Ltd., Distt- Bareilly, U.P |

| 67. | M/s Dhampur Sugar Mills Ltd., Dhampur Distt- Bijnor, U.P. |

| 68. | M/s Triveni Engineering & Industries Ltd., Sugar Unit- Deoband, Distt- Saharanpur,U.P. |

| 69. | M/s HPCL, Bio Fuels Ltd., Unit- Suguali, East Champaran, Bihar |

| 70. | M/s Nanglamal Sugar Complex, Distt- Meerut, U.P. |

| 71. | M/s PMV Maltings Pvt. Ltd., Mahua Khera Ganj Kashipur, Distt- U.S. Nagar Uttarkhand |

| 72. | M/s Mankapur Chini Mills Ltd., Unit of Balrampur Chini Mills Distt- Gonda, U.P. |

RESEARCH ARTICLE:

“BIOMASS ENERGY FOR ECONOMIC & ENVIRONMENTAL SUSTAINABILITY IN INDIA"

By

Narendra Mohan & Anoop Kumar Kanaujia

National Sugar Institute

Kanpur

Abstract

India is the second largest producer after Brazil producing nearly 15 and 25 % of global sugar and sugarcane respectively and is the top most consumer of the sugar in the world. The sugar industry which encompasses more than 530 operating sugar mills, 175 integrated distilleries and 250 co-generation plants is faced with a reality that sugar, molasses and bagasse can no longer be regarded as final product from sugar industry and thus, value additions, diversifications and transformations to be vigorously investigated as possible routes to new market and making sugar industry less dependent on single commodity i.e. sugar. The future of the sugar industry, as a whole, lies in development of sugarcane bio-refineries i.e. bio-electricity, bio-ethanol, bio-manure and chemicals etc.

Keywords— Biomass, Bio-ethanol, Bio-electricity.

Introduction

Conventional sugar factories process sugarcane to obtain crystal sugar, molasses and energy co-products from bagasse. At present, only about 40% of the Indian sugar factories are carrying out power export to national grid, whereas, the number of ethanol units attached to sugar factories is still lower. Hence, the potential of value addition through better utilization of by-products even in the most common manner is not fully harnessed. Utilization of by-products even in the most generalized manner, thus, can not only perk up the financial health of the sugar industry but also in meeting the scarcity of power and ethanol for EBP programme, the green energy in either case.

The sugar industry across the globe is also required to work on the mandate developing “Wealth from Waste” or converting “Waste to Resource” utilizing anything which is available with sugarcane or is generated in one or other form of processing. Thus, for sustainability of the Indian sugar industry or sugar industry as a whole, it includes improvement in the sugarcane and sugar productivities, conversion from single-product to multi-product factory, optimizing cost of sugarcane processing, integration with food processing industry, utilization of huge infrastructure during off-season, adoption of hybrid system for power generation i.e. biomass: solar: wind power and finally conversion of existing sugar factories to bio-refineries [1].

Fig.1 -Bio-Refineries

Bio-Electricity

Sugarcane is one of the most promising agricultural sources of biomass energy in India and elsewhere. Sugarcane produces mainly two types of biomass, cane trash and bagasse. Bagasse is usually combusted in boiler furnaces to produce steam for power generation but now is also being considered as an emerging & attractive feedstock for bio-ethanol production. Bagasse based co-generation is one of the most attractive and successful power projects that have already been demonstrated in many sugar factories in India.

Advantages of Bio-Electricity

Generating bio-electricity offers numerous benefits as; an abundant & renewable source and of high potential to substitute fossil fuels to meet energy demands of the country. It provides clean energy because of neutral emission of carbon dioxide (CO2) [2]. It also helps sugar mills to meet 100% of their energy needs, furthermore, the opportunity to sell surplus electricity to grid. There is reduction of environmental pollution in relation to use of fossil fuels [3].The energy/emission savings in co-generation plants also generate Clean Development Mechanism (CDM) [4]. Further, it assists in modernizing the rural areas by promoting sustainable rural growth.

Indian Electricity Sector Scenario

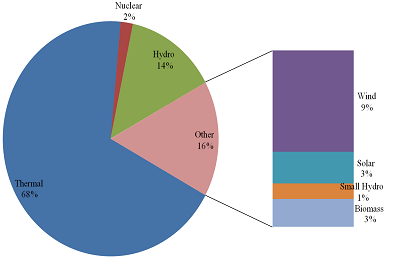

The utility electricity sector in India had an installed capacity of 314.0 GW as on 31 December 2016. Renewable power plants constitute 50.0 GW i.e. 16% of total installed capacity, out of which, contribution of biomass based cogenerated power is 7.9 GW i.e. 15.9% of total installed Renewable Energy Sources (RES) capacity. RES include Small Hydro Projects, Biomass Power, Urban & Industrial Waste Power, Solar and Wind Energy.

Fig. 2 -Installed Power Capacity in India as on December, 2016

Source: CEA Data 2016

During last five years, the installed biomass power capacity has increased by about 150% and is targeted to 10.0 GW by 2020, in which the bagasse based co-generated power can play a vital role.The current exportable energy from excess bagasse in sugar factories is about 3200 MW, which is 1.0% of the national electricity generation, with only part of the sugar factories undertaking power export and also as only about one-third sugar factories out of 250 co-generating sugar factories have high pressure co-generation. With the availability of advanced co-generation technologies, sugar factories can harness the onsite bagasse resource to go beyond meeting their own energy requirements and produce more surplus electricity for sale to the national grid or directly.

POTENTIAL OF POWER EXPORT FROM INDIAN SUGAR INDUSTRY

The potential of the sugarcane industry nationwide is estimated as around 10.0 GW that can be exported to the grid on the basis of power generation @ around 150 kWh per tonnes of cane processed using the latest commercially proven co-generation technologies. New technologies like steam parameters with extra high pressure & temperature configuration, modified design of fuel handling system and furnaces, higher blending of other biomass along with bagasse, improvements in pollution control devices and water treatment plants etc. have to be made to increase the potential to this level. The exportable power potential may be further increased by around 20% i.e. to 12.0 GW after installation of bagasse drying system [5].

Table I- Power Export Potential in Different Models of Co-Generation

| Pressure(ATA) | Cane Crushed (MMT) | Bagasse Available(MMT) | Exportable Power (MW) | Power from Cane Trash(MW) | Total Exportable Power(MW) |

|---|---|---|---|---|---|

| 67 | 273.68 | 79.37 | 3712.48 | 800 | 4512.48 |

| 125 | 273.68 | 79.37 | 8842.59 | 1500 | 10342.59 |

MMT Million metric tonnes

Presently direct-combustion technology to generate steam for production of electricity through condensing-extraction steam turbine (CEST) system is dominant, but the future is focused on the introduction of high-efficiency gasification combined-cycle systems [6]. The potential of power generation in such case may as high as 225-250 kWh per ton of cane as compared to 120-150 kWh through CEST system.

Bio-Ethanol

Global concern about climate change and the consequent need to diminish greenhouse gases emissions have encouraged the use of bio-ethanol as a gasoline replacement or additive. Bio-ethanol may also be used as raw material for the production of different chemicals, thus driving a full renewable chemical industry. In recent years, energy consumption and global carbon intensity (the ratio between carbon emissions and energy supplied) have increased worldwide, reinvigorating worries about potential depletion of fossil fuel reserves. Such increase, accompanied by growing political instability in oilproducing regions, has instigated many countries to search for alternative forms of energy [7]. In most cases, this alternative source is renewable, since the CO2 emitted into the atmosphere is recaptured by the growing crop in the next growth cycle. Ethanol from sugarcane is one of the most promising bio-fuels because its energetic balance is generally positive, meaning that the growing sugarcane absorbs more carbon than is emitted when the ethanol is burned as fuel.

Ethanol (EtOH) may be produced using sugarcane bagasse as raw material through the organosolv process with dilute acid hydrolysis, thus increasing ethanol production with the same cultivated sugarcane area [8]. With other techniques for producing cellulosic ethanol are in the process of commercialization, the area, however, requires in intensive study before adopting any technology on commercial scale with respect to economics of production and comparative advantages between power generation viz-a-viz EtOH production. U.S. Environmental Protection Agency (EPA) classified that sugarcane ethanol as capable of reducing green house gas (GHG) emissions by at least 50% compared to gasoline [9]. Roughly, one ton of sugarcane biomass based on sugar, bagasse and ethanol output has an energy content equivalent to one & half barrel of crude oil [9].

Overview of Indian Alcohol Industry

India, at present, targeting ethanol blending @ 10% in petrol, produces it mainly by molasses route. The installed capacity of about 6250 million liters per annum (3/4th molasses and 1/4th grain based) is grossly under utilized due to shortage of raw material i.e. molasses. Statistically, India produces about 3% and 1% of the world alcohol and fuel alcohol respectively. The conventional route, keeping in view the potential of overall alcohol production and its sector-wise demand, is estimated to cope up with EBP 5 only (i.e. approx. 1300 million liters per annum).

Considering 5% diversion of molasses for export, cattle feed, other uses and wastage/deterioration etc. and assuming an average realistic yield of alcohol @ 235 liters/ton of molasses (considering average Total Reducing Sugar Content as approx. 47.5)

Table II-Molasses and Estimated Alcohol Production Potential

| Sugar Season | Total Molasses Production (million tons) | Molasses Available for Alcohol Production (million tons) | Estimated Alcohol Production Potential (million liters) |

|---|---|---|---|

| 2012-13 | 11.74 | 11.15 | 2621.9 |

| 2013-14 | 10.88 | 10.32 | 2429.5 |

| 2014-15 | 12.48 | 11.85 | 2786.6 |

Alternate Feed Stocks for Alcohol Production

At the prevailing sugarcane prices and estimated yield of alcohol per ton of sugarcane, the proposition may not be viable. However, under the situation of excess sugar production, lower sugar prices and favorable market economics, its diversion or diversion of other process liquors e.g. secondary juice, filtrate juice or intermediate molasses may be considered. The diversion shall result into:

1. Better capacity utilization of the distilleries.

2. Variation on the ratio of sugar and ethanol produced according to the market, resulting in sugar price stabilization and coping up with the requirement of EtOH for EBP.

3. Sugar of better quality – no need to recycle molasses or juices of low purity and thus price premium over the produce

Potential of EtOH production may be harnessed by utilizing Cassava, Sugar Beet and Sweet Sorghum as available in different agro-climatic zones. As discussed earlier, more work shall be required to develop a cost effective, indigenous technology for production of EtOH from ligno-cellulosic material including bagasse. It may not be out of place to mention that vinasse/ spent wash, the effluent of ethanol production may turn out to be a key source of bio-energy either by transforming it into biogas (methane), which can be used as boiler fuel or after concentrating it in Multiple Effect Evaporators (MEE) and then to incinerate along with bagasse/coal/other bio-mass in an incineration boiler integrated with turbine to produce the bio-electricity [10].

Conclusion

As discussed, green energy is one of the most efficient ways to achieve sustainable development. Increasing its share in the world matrix will help prolong the existence of fossil fuel reserves, address the threats posed by climate change, and enable better security of the energy supply on a global scale. Most of the “new renewable energy sources” are still undergoing large-scale commercial development, but some technologies are already well established. These include sugarcane ethanol, which, is a global energy commodity that is fully competitive with motor gasoline and appropriate for replication in many countries.

In the near future, the bio-refinery concept of complete utilization of sugarcane biomass will become a pivotal element for a sustainable sugarcane industry. An industry that produces liquid fuels, electricity and commodity chemicals from a renewable source in regional communities will contribute to all elements of the triple bottom line and should be considered a compelling vision.

References

[1] L. A. Edye, W. O. S. Doherty, and J. A. Blinco et al., “The Sugarcane Bio-Refienry: Energy Crops And Processes For The Production Of Liquid Fuels And Renewable Commodity Chemicals,” in Proc. Aust. Soc. Sugar Cane Technol., 2005, vol. 27, pp. 9–22

[2] S. Jenjariyakosoln, B. Sajjakulnukit, and S. Garivait, “Energy and Greenhouse Gas Emissions Reduction Potential of Sugarcane Field Residues Power Generation in Thailand,” in International Journal of Environmental Science and Development, 2013, vol. 4, no. 2, pp. 182–186.

[3] T. C. Cannavam, W. F. Molina, and M. L. Cunali, “Energy Potential Of Sugar Cane Biomass In Brazil,” in Scientia Agricola, 2000, vol. 57, no. 4, pp. 677–681.

[4] Anonymous, “Bio-Ethanol As Major Source Of Energy,” in National Development and Reform Commission (NDRC) http://www.hedon.info/docs, 2007, pp. 1–15.

[5] A. K. Kanaujia and D. Swain, “Bagasse Drying - A Green & Efficient Solution To Significantly Meet Out Power Deficit In India,” in Proceedings of 11th Joint Convention of STAI & DSTA, 2015, pp. 390–398.

[6] N. Mohan, J. P. Srivastava, and A. K. Kanaujia, “Bagasse Gasification - An Energy Efficient Option,” in Proceedings of 11th Joint Convention of STAI & DSTA, 2015, pp. 399–405.

[7] L. A. Martinelli and S. Filoso, “Expansion Of Sugarcane Ethanol Production In Brazil: Environmental And Social Challenges,” in Ecological Applications, 2008, vol. 18, no. 4, pp. 885–898.

[8] M. O. S. Dias, A. V. Ensinas, and S. A. Nebra et al., “Production Of Bioethanol And Other Bio-based Materials From Sugarcane Bagasse : Integration To Conventional Bioethanol Production Process,” in Chemical Engineering Research and Design, 2009, vol. 87, pp. 1206–1216.

[9] Anonymous, “Renewable Energy Brazil,” in PWC https://brazilianchamber.org, 2013.

[10] P. Patel and S. Gaikwad, “Spent Wash Incineration Technology For Sugar & Distillery Sector To Achieve Zero Liquid Discharge,” in Proceedings of 11th Joint Convention of STAI & DSTA, 2015, pp. 788–798.

HAPPENING IN THE SUGAR INDUSTRY:

Diwali dhamaka may not rattle sugar.

Sugar prices have declined in the past two weeks and are expected to remain range-bound till Diwali, giving respite to consumers during the festival period when demand and prices typically increase. Post Diwali, while analysts expect the downturn to continue, the industry is hopeful that prices will remain stable.

UP sugar mills demand status quo on cane prices.

Sugar mills in Uttar Pradesh have urged the State government not to increase sugarcane prices to be given to the farmers as it would hit them. This is even as the State is likely to register a record sugar output of around 10 million tonnes in the forthcoming season starting next month.

Status quo on cane prices demanded by UP sugar mills.

In order to protect the interest of farmers, sugar mills in Uttar Pradesh have urged the state government to not increase the sugarcane prices to be given to farmers. The state government is expecting to register a record sugar output of approximately 10 million tonnes from the next month.

UP: Paniji sugar mill to start again.

मायावती शासनकाल में बेची गई पन्नीजी शुगर मिल का मंगलवार को भूमि पूजन किया गया। इस मौके पर गन्ना मंत्री सुरेश राणा ने कहा कि पिछली सरकार ने चीनी मिलों को चलती हुई हालत में बेचा था तो मिले चलेंगी। साथ ही उन्होंने कहा कि मिल को चालू कराने के लिए गन्ना आयुक्त, गन्ना अधिकारी और जिलाधिकारी की टीम को नियुक्त कर दिया गया है। मिल को जल्दी से जल्दी शुरू कराया जाएगा। वही, दूसरी तरफ प्रदषाण नियंत्रण बोर्ड के अधिकारियों का कहना है कि जब तक वेव शुगर मिल एनजीटी के मानक पुरे नही करेगी, तब तक मिल शुरू नहीं हो सकती।

Farmers protest as Kinoni sugar mill yet to clear pending dues.

Meerut: Unable to pay the school fee of their children and buy basic necessities, sugarcane farmers under the banner of Jat Mahasabha (Meerut unit) on Wednesday came together to protest against Kinoni sugar mill management for not clearing their pending dues of nearly Rs 105 crore.

Sugar prices dilute on soaring stocks.

New Delhi, Sugar prices notched down by Rs 50 per quintal at the wholesale market in the national capital today, pulled down by ample stocks on availability due to relentless supplies from mills amid negligible buying support from stockists and bulk consumers.

Sugarcane crushing season to start early; bumper production eyed.

Uttar Pradesh, which is looking at a bumper sugar production of over 10 million tonne in 2017-18, is gearing up to start sugarcane crushing early this year, starting October. As many as 60-odd sugar mills have given their tentative consent to start crushing in October.

TN State Government urged to bail out sugar sector.

The South India Sugar Mills Association (SISMA) has urged the State Government to bail out sugar industries and extend ₹ 300 per tonne as subsidy to farmers. Speaking to reporters on the sidelines of the international symposium on ‘Sugarcane Research Since Co 205: 100 Years and Beyond – SUCROSYM 2017’.

UP: Bahraich Sugar mill's crushing to start in November.

बहराइच जरवलरोड स्थित आईपीएल चीनी मिल में पेराई सत्र नवंबर माह में शु :रू होगा। इससे किसानों को गेहूं बोने में आसानी होगी। मिल के नावगंतुक महाप्रबंधक एके सह ने बताया कि गन्ना किसानों की समस्याओं के निराकरण के लिए वे कृत संकलिप्ति हैं।

Maha: BJP joins hands with NCP sugar factory election in Kagal.

Bharatiya Janata Party (BJP) has joined hands with Nationalist Congress Party (NCP) for election at Dudhganga Vedganga Co-operative Sugar Factory in Kagal . The development is considered important since the BJP has frequently labelled the NCP as a corrupt party and blamed the party for deteriorating the cooperative sector.

Sugar prices climb on strong demand, tight supply.

Sugar prices spurted by Rs 50 per quintal at the wholesale market in the national capital today following brisk buying by stockists and bulk consumers ahead of festive season coupled with halt in supplies from mills.

Maha: Sugarcane makes the mighty Bhima weak.

Maharashtra's second longest river, the Bhima, perhaps serves sugarcane plantations and sugar mills more than the human population of the state. Consider this: a staggering 273 dams have been built in the Upper Bhima basin across the state and 90% of canal water diverted from such dams is used to irrigate sugarcane.

Sugarcane Committee's to be audit from CAG.

प्रदेश के गन्ना राज्यमंत्री सुरेश राणा ने बिजनौर में कहा कि प्रदेश सरकार ने तय कर दिया है कि गन्ना किसानों को हर हाल में उनकी उपज का समय पर भुगतान मिलेगा। चीनी बिक्री के बाद मिलों को मिलने वाला पैसा जिला गन्ना अधिकारी और संबंधित मिल के अध्यासी के संयुक्त खाते में जमा होगी। जहां से 85 प्रतिशि भुगतान किसानों को कर दिया जाएगा।

New device harvests energy from waste heat.

Researchers at Duke University have created the first MEMS (microelectromechanical system) metamaterial device that emits patterns of thermal infrared light in a completely controllable manner, making harvesting energy from waste heat a real possibility.

Argentina – 2017 likely to be a record for biofuels output.

First quarter data on biofuels output in Argentina suggests that it will be a record according to the National Institute of Statistics and Censuses (INDEC).

US researchers develop a process to convert paper waste into carbon fibre

In USA alone, some 50 million tonnes of lignin-rich paper is discarded as waste. Currently, only about two percent is recycled into new products, such as the bioplastic Arboform. Researchers at Texas A&A Agrilife have developed a method for converting waste from the paper and pulp industries into carbon fibres that have variety of applications.

Annellotech successfully demonstrates its biomass-to-aromatics technology at its pilot plant.

The biotech start-up Anellotech recently announced that its and IFPEN/Axens engineers have successfully completed a continuous performance test of the TCat-8 pilot plant as part of unit commissioning in Silsbee, Texas, USA.

Brazil – Mills buying back sugar contracts.

As the second quarter of the 2017/18 sugarcane crop starts, few mills have begun repurchasing some of the sugar they had agreed to deliver to trading firms this season, leaving a bigger share of the commodity without a set price.

Researchers devise way to reduce the amount of enzymes needed in the production of cellulosic biofuels.

Nonspecific adsorption of cellulases to lignin hinders enzymatic biomass deconstruction. Researchers at Rutgers University-New Brunswick and Michigan State University have demonstrated how to design and genetically engineer enzyme surfaces so they bind less to lignocellulosic feedstocks, reducing enzyme costs in the production of cellulosic biofuels production.

Sugar power turns into bitter tiff between Maharashtra government, mills.

The impasse between the Maharashtra government and sugar millers on Power Purchase Agreements (PPAs) for co-generation projects continues. Maharashtra cooperation minister Subhash Deshmukh has asked the sugar millers to seek fair rates for power for their co-generation projects instead of demanding rates as high as Rs 6.50 per unit.

Demonisation of sugar as a sin product must be based on evidence: Jose Orive, ED at ISO.

José Orive, executive director at London-based International Sugar Organization (ISO), says the cane payment systems across nations present a rainbow of colours and India must pick up a system in which all the key stakeholders win. In an interview to FE, he says global sugar surplus in 2017-18 would be more than anticipated.

Co 205 sugarcane variety turns 100.

The Sugarcane Breeding Institute (SBI) is organising an international symposium – SucroSym 2017 – from September 18 to 21 in Coimbatore. The symposium is to commemorate the 100th year of release of Co 205, the first inter-specific commercial cane hybrid variety, which according to Bakshi Ram, Director, Sugarcane Breeding Institute, revolutionised cane cultivation in the country.

Maharashtra cane crop reels under white grub pest attack.

Sugarcane crop in South and Central Maharashtra, the key growing regions, has suffered extensive damage due to pest attacks, and yields could dip by 10-15 per cent in the twin regions, causing extensive loss to farmers.

Sugar prices decline on bumper stocks, muted demand.

Sugar prices settled lower by Rs 30 per quintal at the wholesale market in the national capital today on slackened demand amid non-stop supplies from mills. Marketmen said bloated ready stocks on consistent supplies from mills amidst limited offtake by stockist and bulk consumers, mainly brought down the sweetener prices.

Imported sugar to get cheaper in south India.

With domestic sugar prices in the wholesale market quoted at around Rs 39 a kg, imported sugar continues to remain cost-effective in southern states even with a 25 per cent duty. In Tamil Nadu, sugar is priced Rs 1.50-2 a kg more than that in Maharashtra due to supply shortage.

Sugar prices fall on higher stocks, low demand

Sugar prices weakened by Rs 35 per quintal at the wholesale market in the national capital today due to bumper stocks following increased supplies against muted demand from bulk consumers as well as retailers. Marketmen said fall in offtake by stockists and bulk consumers amid relentless supplies from mills mainly led to the fall in sweetener prices.

Maharashtra sugar sector in trouble, says Sharad Pawar.

Sharad Pawar, chairman, Vasantdada Sugar Institute (VSI) on Saturday said the sugar sector in Maharashtra is in trouble and has lost it’s place as the country’s top producer to Uttar Pradesh (UP). Therefore, a lot needs to be done for Maharashtra to regain the top slot.

22k farmers get loan waiver certificates in Bijnor

Times of India - 9 September 2017, Bijnor: As many as 22,000 farmers in Bijnor were awarded loan waiver certificates on Friday. The certificates were given out at a function by the minister in-charge of the district. In Bijnor, agricultural loans of 22,156 farmers amounting to Rs 146 crore have been waived off. Recently, this amount was transferred to the bank account of the beneficiaries.

Crushing at PSSK soon: Puttannaiah.

K. S. Puttannaiah, MLA has said that with Chief Minister Siddaramaiah agreeing to release Rs 2 crore working capital, the Pandavapura Sahakari Sakkare Kharkane (PSSK) will soon start crushing activities for the year 2017-18.

SriRama Sugar factory in K.R. Nagar to be leased.

The State Government has decided to let out Srirama Co-operative Sugar factory in Chunchanakatte, K.R. Nagar on lease for a 40-year period to private parties. This decision was taken at a meeting chaired by Chief Minister Siddharamaiah at the CM’s home office ‘Krishna’ here on Thursday.

Cooperative sugar mills oppose move to impose stockholding restrictions.

Cooperative sector sugar mills across the country have stated that the impact of the stock limit will dampen the cooperative sugar sector. The National Federation of Cooperative Sugar Factories (NFCSF) has expressed concern that the decision to impose stock limits is likely to result in dropping the ex-mill realisation below the current level of Rs 3,650 per quintal in addition to GST and this may adversely affect the timely cane payment to farmers across the country.

Sugar mills ready to pay dues of farmers after CM tough stand.

मुख्यमंत्री त्रिवेन्द्र सिंह रावत ने बुधवार को सचिवालय में गन्ना-चीनी विभाग की समीक्षा की. मुख्यमंत्री ने सरकारी और निजी दोनों ही श्रेणियों की चीनी मिलों को घाटे से उबारने के सलए ठोस कार्य योजना प्रस्तुत करने के निर्देश दिए।

‘Meetha Sona’ Hoping to Sweeten Agriculture for Cane Farmers in Uttar Pradesh.

Coca-Cola and its partners are working with the agricultural community in Uttar Pradesh for the 'Meetha Sona' project. The project is looking to enhance the capacities and knowledge of farmers towards sustainable cultivation of sugarcane. Farmers will also be trained on good agricultural practices, efficient use of water and smart pest management practices.

Sugarcane sowing will start soon in this season.

इस्मा के महानिदेशक अविनाश वर्मा ने कहा, 'उत्तर प्रदेश, महाराष्ट्र, कर्नाटक और तमिलनाडु की बहुत सी चीनी मिलों ने हमें लिखित में दिया गया है कि वे इस साल अक्टूबर के मध्य तक पेराई शुरू कर देंगी।

छह राज्यों में होगा यूपीसीएसआर की नौ गन्ना प्रजातियों का ट्रायल.

गन्ना शोध परिषद की नौ गन्ना प्रजातियों को छह राज्यों में परीक्षण के लिए चुना गया है। आखिल भारतीय शोध समन्वित परियोजना की बैठक में स्वीकृति के बाद परिषद की इन गन्ना प्रजातियां का यूपी, उत्तराखंड, पंजाब, हरियाणा, बिहार तथा असम में परीक्षण किया जाएगा।

UP: Relief for cane farmers.

प्रदेश सरकार इस बार ऐसे किसानों का जल्द भुगतान करेगी जिनके घरों में बेटियों की शादी है या कोई आकस्मिक समस्या आ गई है। वैसे तो गन्ने का भुगताान 14 दिन में होता है लेकिन इस स्थिति में एक या दो दिन के अंदर ही गन्ना बिक्री का पूरा पैसा किसान के खाते में आ जाएगा।

As cane ripens, farmers fear crop damage by elephants.

Farmers cultivating sugarcane in the areas bordering the forests fear that elephants may enter their fields and destroy their almost ripe cane crop. Sugarcane is one of the favourite foods of elephants and when herds come to feed, they damage standing crops. Sometimes, the animals attack humans as well.

Australia – MSF Sugar gets funding to grow agave for cogen plant during off season

The Queensland state government announced on 10th July its support for the AU$60- million (US$ 45.5 mln) for the MSF Sugar biorefinery project on the Atherton Tableland in the state. This includes the production of agave that will be used as a feedstock for the cogen plant during the off season. As such, the aim is for the plant to be operational for 12 months.

Canada – Rogers Sugar buys local maple syrup producer for US$124 million.

The 127-year-old Canadian sugar refiner Rogers Sugar and parent company of Montreal’s Lantic Inc. has agreed to acquire a maple syrup bottling and distribution company from Quebec holding firm Champlain Financial Corp for CA$160.3 million (US$124 mln) in cash, according to a statement released by the company on 10th July.

Genetics dictates crop yield limitation.

Researchers at the John Innes Centre, UK shows that the plant’s own genetics may be the real limiting factor rather than relative access to nutrition, water and sunlight.

UK – 2017/18 beet acreage increases by a third.

Beet acreage in the UK has risen even faster than those in many other European Union countries, ahead of the impending Brexit as well as the abolition of sugar quotas in the bloc in October.

USA – New Planet Energy plans to build waste-to-biofuels US$700 mln plant in New York.

New Planet Energy is proposing to build a US$700 million recycling plant that will convert the region’s municipal garbage into fuel in Stony Point.

Belgium – New €300 mln beet sugar factory proposed.

Based on a co-operative model, a new 14,000 t beet/day factory, sited probably in the main beet growing region of Wallonia, is proposed by the administrators of the Association of Walloon beet growers (ABW), according to local press reports.

Transfer formalities delay sugar unit’s makeover.

The government's decision to transfer the 45-year-old Sanjivani factory at Dayanandnagar, Dharbandora, from the agriculture department to the cooperation department has delayed the factory's modernization for a year. Modernization of the plant would be a central government project under the Rashtriya Krishi Yojana (National Agricultural Scheme) wherein Goa's share in expenditure would be 25%, while the centre would bear the rest of the costs.

Maharashtra sugar mills hesitant on early start to crushing season.

Even as the Centre has turned down the demand for compensation put forth by private sugar mills in Maharashtra for starting the crushing season early, millers in the state still remain hesitant about commencing the crushing season in the first week of October. Maharashtra State Cooperative Sugar Factories Federation chairman Shivajirao Nagawade says mills .

Sugar stocks turn sweet on reports of possible hike in ethanol prices.

Shares of seven sugar companies rose 0.29% to 3.3% at 14:30 IST on BSE after reports suggested that the food minister has asked for Rs 2 per litre hike in ethanol prices sold to Oil Marketing Companies. Meanwhile, the S&P BSE Sensex was up 56.39 points.

Traders warned against illegal hike in sugar prices.

Commissioner for Civil Supplies C.V. Anand warned sugar traders against hiking the price by creating scarcity by stock holding of sugar illegally and practicing of speculative activities. “Licensed Dealer / Trader should not sell sugar more than the price decided by Central government or state government.

UP: M-Kissan portal for cane farmers.

उत्तर प्रदेश के गन्ना किसान टेक्नोलाजी का लाभ उठाकर गन्ने की खेती से लाभ कमा सकें इसके सलए प्रदेश के सभी 33 लाख गन्ना किसानों को "एम-किसान पोर्टल " से जोडा जाएगा। यह घोषणा गन्ना विकास एवं चीनी उद्योग मंत्री ( स्ववंत्र प्रभार ) सुरेश राणा ने की।

Cane dues at Rs 2K crore-plus even after 5 months of Yogi Adityanath govt.

More than five months after the Yogi Adityanath government assumed office, sugar mills in Uttar Pradesh (UP) are still to pay farmers over Rs 2,000 crore against past cane purchases. This, despite the Bharatiya Janata Party (BJP) in its 2017 UP election manifesto promising to clear all pending dues of growers within 120days of coming to power, and ensuring future payments in less than 14 days of cane supply.

A tough balancing act: The new bitter North-South divide in India’s sugar industry.

India’s sugar industry seems headed for a North-South divide, with drought conditions leading to huge cane shortages in Karnataka and Tamil Nadu, even as Uttar Pradesh (UP) is poised for a second straight year of record production.

Bajaj Hindusthan Sugar posts Q1 net loss of Rs25 crore.

Bajaj Hindusthan Sugar Ltd on Monday reported a net loss of Rs25.08 crore for the quarter ended June on higher expenses. Its net loss stood at Rs77.38 crore in the year-ago period. Total income increased to Rs1,798.06 crore in the first quarter of this fiscal from Rs 1,379.35 crore in the year-ago .

European Commission’s Sugar Market Observatory commences operations.

The European Sugar Market Observatory created by the European Commission last March started operating on 11th July.

Australia – Queensland likely to get Amyris’ cane-based farnesene plant.

The US biotech start-up Amyris recently announced that it will partner with the Queensland government in Australia to open a biorefinery as part of the state’s vision to produce AU$1 billion (US$760 million) of sustainable, export-oriented biotechnology products.

Belize – ASR Group drives productivity to make the sugar industry competitive.

The American Sugar Refining (ASR) Group, owners of Belize Sugar Industries (BSI), is planning to drive productivity to make the local industry more competitive as it faces low world price of sugar and loss of preferential to European market later this year.

Mozambique – Tongaat to build a backend refinery at Xinavane mill.

Tongaat Hulett said on 24th July it will build a refinery at its Mozambican sugar mill to produce refined white sugar for which there is a growing shortage, with the country importing 90% of its needs.

China – Increase in output of the cheaper HFCS rattles local sugar market.

Output of HFCS (high-fructose corn syrup) in China is set to jump 7% this year, according to commodities information service Zhuochuang, as cheap corn from a sell-down of the country’s giant stockpiles encourages producers to boost output or restart idled capacity, reported Reuters.

Israel – Kiryat Gat sugar refinery to be closed down by end of the year.

Sugat announced on 2nd July that it would close down its sugar refinery in Kiryat Gat in six months, according to local press reports.

Gen3Bio’s process produces chemicals from microalgae.

The biotech start-up Gen3Bio is developing a novel process that could more effectively and affordably transform microalgae into chemicals.

How flip-flops on sugar imports to bring down prices led to rates being stuck in Rs 40-Rs 45/kg range.

A broad analysis of the sugar market from 2009 onwards till July 2017 reveals that a trend of sugar prices remaining bullish. Retail sugar prices rose from Rs 29/kg in 2009 to Rs 32- 35/kg in 2014—climbing by 20%. In the recent past, sugar climbed up from Rs 31/kg in 2015 to Rs 39/kg in.

Sonipat protested outside sugar mill.

सोनीपत में बुधवार को सैकड़ों किसानों ने अपनी मांगों को लेकर प्रदर्शन किया. किसानों ने पहले शुगर मिल के बाहर मिल प्रबंधन के खिलाफ प्रदर्शन किया और फिर सरकार के खिलाफ भी जमकर नारेबाजी की. उसके बाद किसानों ने ट्रैक्ट्र्रों पर सवार होकर शहर भर में रोष मार्च निकला और लघुसचिवालय पहुंचा.

Southern Maharashtra sugar mills unlikely to start ops before Diwali.

Sugar mills from southern Maharashtra may not be able to start operations before Diwali, even as the industry and government are preparing for advance sugarcane crushing operations by a month to October to tide over any shortages during the festival season.

Indian Scientists Turn Sugar Industry Waste Into Next-Gen Battery Material.

Indian scientists have demonstrated that waste water from some of the dirtiest industrial processes can be turned into a carbon source for preparation of energy storage materials. Researchers led by scientists from Bhavnagar-based Central Salt and Marine Research Institute (CSMRI) have used sugar and distillery industry waste to develop functionalized carbon material which has energy storage properties.

Enough sugar for this year, assures ISMA.

There are sufficient sugar stocks in India to take the country through the next sugar marketing year, trade body Indian Sugar Mills Association (ISMA) said. This came amid reports that the government is contemplating another round of sugar imports to meet the anticipated high demand during the upcoming festival season.

Ugar Sugar expects KPCB order to start production shortly.

After receiving a closure notice from the Karnataka Pollution Control Board (KPCB), Ugar Sugar Works today said the company is trying to get an order to carry out production activities shortly. In a BSE filing, the company said: "KPCB has revised the order on August 7, 2017 .

India plans to allow extra 200,000 tonnes duty-free sugar imports: source.

India is planning to allow additional 200,000 tonnes of duty-free sugar imports, a government source said on Tuesday, as production fell below consumption in 2016-17 marketing year ending on September 30. The world's biggest sugar consumer had earlier allowed duty-free imports of 500,000 tonnes of the sweetener.

In UP we are looking at volume growth: Balrampur Chini Mills.

In an interview with ET Now, Vivek Saraogi , MD, Balrampur Chini Mills said that,"UP would probably produce 40% of the country’s overall sugar production next year and I think it is the best list."

Medium sugar firms up on sustained demand.

Medium sugar firmed up modestly at the Vashi wholesale market here today due to sustained demand from stockists and retailers. While small sugar maintained mixed trend owing to alternate bouts of buying and selling. Medium sugar (M-30) moved up by Rs 10 per quintal to Rs 3,760/4,016 from Monday's closing level .

Sugarcane development board to construct road.

गन्ना विकास परिषद सभी क्षेत्रों में तीन करोड की लागत से सडकों का निर्माण कराएगा। यह निर्णय परिषद की बैठक में लिया गया। पीलीभीत गन्ना विकास परिषद की बैठक चेयरमैन रवित अग्रवाल की अध्यक्षता में हुई। एससीडीआई ने गत कार्रवाई को पढ़कर सुनाया। इसके बाद सदस्यों ने एजेंडे पर चर्चा शुरू की।

UP: No sweet news for cane farmers.

उत्तर प्रदेश में गन्ने का मूल्य तय करने के लिए रंगराजन फ़ॉर्मूले की सिफारिश पर अमल की प्रक्रिया तेंज हो गई है। केद्रीय उपभोक्ता मंत्रालय ने राज्य सरकार को पत्र लिखा है, जिसमें राज्य समर्थित मूल्य यानी एसएपी को समाप्त कर एफआरपी यानी फेयर रिम्युरेटीव प्राइज नीति की वकालत की गई है।

Uttarakhand: Sugar cane area increased.

जिले में इस बार गन्ने का क्षेत्रफल बढ़ गया है। गन्ना विभाग ने सर्वे कर रिपोर्ट शासन को भेज दी है। गन्ना विभाग की रिपोर्टसे चीनी मिलों की भी बांछे खिल गई हैं। इस बार किसानों ने चीनी मिलों के मन की मुराद पूरी कर दी है।

Revival of Amadalavalasa sugar factory sought.

Opposition parties and a few NGOs joined hands for the revival of the Amadalavalasa Cooperative Sugar factory which was closed in 2003. Accumulated losses of ₹30 crore made the government to issue orders for its closure. Sugarcane was grown in 80,000 acres when Amadalavalasa sugar factory was in operation.

Sugar stocks become sweeter.

Sugar stocks were buzzing during the morning hours on Monday on the BSE. Empee Sugars & Chemicals was the top gainer among them and the stock breached the upper circuit at Rs 6.10, up by 4.99%. It witnessed spurt in volume by more than 1.03 times.

Why India's sugar production in 2017-18 will leave a bitter taste in the mouth.

The next time you add that extra spoon of sugar in your cuppa, take a second look, as the current season and the next holds the promise of sugar turning into precious white crystals. India’s sugar production scenario is perched on a precarious ground, for the current year and for the next year as well.

Brazil – Millers tilting towards the increasingly profitable ethanol rather than sugar.

Following two years of high global sugar prices which attracted the export market, mills in the Center-South region are beginning to focus ethanol production as it is offering a better return than sugar, reports Valor Economico.

Researchers convert CO2 into multi-carbon fuels.

Researchers at the California Institute of Technology discovered a new way to produce carbon-based liquid fuels from CO2.

Spain – New €424 million beet sugar factory awaits planning approval.

The municipality of Extremadura received in May planning permission to build a new beet sugar factory in the industrial park Expacio Mérida (Badajoz). A range of supporting documents has been submitted to the Environment and Rural division which includes both the application for the new build and environmental impact study.

Vietnam – Couple of local sugar producers merge to compete with Thai sugar.

Sugar company Thanh Thanh Cong Tay Ninh (SBT) is acquiring Bien Hoa (BHS) in the hope being competitive in both the home and regional market, according to local press reports.

Sri Lanka – Finance ministry increases sugar import levy by US$ 52/tonne.

Sri Lanka’s finance ministry increased an import tax on sugar by LKR 8/kg (US$ 52/tonne), commencing midnight on August 15, according to local press reports.

Malawi enjoys increased allocation in TRQ for the US sugar market this year.

Malawi’s country-specific allocation of the tariff-rate quota (TRQ) for raw cane sugar imports to the United States has increased by 45% in the fiscal year 2017, according to local press reports.

China – Sugar imports in July fall to three-year low.

China’s July sugar imports plunged for a second month to just 60,000 tonnes, the lowest in three years, after Beijing imposed hefty tariffs on foreign arrivals in late May and slashed import permits, customs data showed on 23 August, reported Reuters.

S2G BioChem to build a plant producing xylitol from lignocellulosic feedstock.

The biotech start-up S2G BioChem is planning to build a new demonstration plant in Sarnia, Ontario, Canada that will produce xylitol from lignocellulosic feedstock, in particular, the locally available residues from pulp and paper plants.

Nigeria – Crystal Sugar plans to build new cane sugar factory.

Crystal Sugar has concluded plans to establish a sugar factory in Jigawa State, according to local press reports.

Vietnam – Couple of local sugar producers merge to compete with Thai sugar.

Sugar company Thanh Thanh Cong Tay Ninh (SBT) is acquiring Bien Hoa (BHS) in the hope being competitive in both the home and regional market, according to local press reports.

Sri Lanka – Finance ministry increases sugar import levy by US$ 52/tonne.

Sri Lanka’s finance ministry increased an import tax on sugar by LKR 8/kg (US$ 52/tonne), commencing midnight on August 15, according to local press reports.

Malawi enjoys increased allocation in TRQ for the US sugar market this year.

Malawi’s country-specific allocation of the tariff-rate quota (TRQ) for raw cane sugar imports to the United States has increased by 45% in the fiscal year 2017, according to local press reports.

China – Sugar imports in July fall to three-year low.

China’s July sugar imports plunged for a second month to just 60,000 tonnes, the lowest in three years, after Beijing imposed hefty tariffs on foreign arrivals in late May and slashed import permits, customs data showed on 23 August, reported Reuters.

S2G BioChem to build a plant producing xylitol from lignocellulosic feedstock.

The biotech start-up S2G BioChem is planning to build a new demonstration plant in Sarnia, Ontario, Canada that will produce xylitol from lignocellulosic feedstock, in particular, the locally available residues from pulp and paper plants.

Nigeria – Crystal Sugar plans to build new cane sugar factory.

Crystal Sugar has concluded plans to establish a sugar factory in Jigawa State, according to local press reports.

Uganda – Start-up introduces low cost cane bagasse-based sanitary pads.

Uganda-based new start-up Eco Smart Pads is keeping girls in school by offering them lowcost sanitary products made from sugarcane bagasse.

New enzymes from Novozymes increases ethanol yield.

Novozymes has launched two new enzymes which it claims could reduce the amount of residual sugars in ethanol production by up to 70%.

China – Coastguards commandeer cargo ship smuggling sugar after noticing a language blunder.

Nine suspects have been detained in Yancheng, East China’s Jiangsu Province for smuggling sugar in early September after border police there noticed that the Chinese characters on the prow of the cargo ship, which was loaded with tons of sugar, were printed in a reverse order, according to local press reports.

China – Sugar production and new build activity surges in the progressive beet sector in Inner Mongolia.

Combination of improved farming techniques and increased mechanization in the beet sector in the Chinese region of Inner Mongolia is driving beet sugar production, reports Reuters.

S2G BioChem to build a plant producing xylitol from lignocellulosic feedstock.

The biotech start-up S2G BioChem is planning to build a new demonstration plant in Sarnia, Ontario, Canada that will produce xylitol from lignocellulosic feedstock, in particular, the locally available residues from pulp and paper plants.

India – Government approves imports of 300,000t sugars at 25% duty.

The Food Ministry allowed on 7th September imports of 300,000 tonnes of raw sugar at 25% duty to bridge the gap in the shortage of the sweetener in the South Indian States ahead of the festive season.

Australia – New US$60 mln cogen plant at Tablelands mill on track to be completed.

Civil works for MSF Sugar’s new AU$75 million (US$60 mln) cane bagasse-based 24 MW cogen plant at the Tableland Mill have been completed.

Ethiopia – Construction for the new US$51 ethanol plant at Wonjo Shoa Sugar factory begins in October.

Ethiopia has joined hands with Germany’s Eugen Schmitt Company to build an ethanol plant at the Wonjo Shoa Sugar Factory. The plant is expected to cost US$51 million, according to local press reports.

Novel process to extract sugars from lignocellulosic feedstocks.

Researchers from the University of Delaware (UD) have developed a new process to extract sugars from lignocellulosic feedstocks which they claim is an upgrade on the current technologies used in the sector.

Cuba – Hurricane Irma severely damages cane crop and factories.

Hurricane Irma seriously damaged Cuba´s sugar factories and flooded and flattened an extensive area of sugar cane, according to state-run media.

France – Latest forecast puts beet productivity at record 91.8 t/ha.

Beet growers in France are expecting record yields according to the industry body CGB (confederation of beet growers).

Canada – Redpath Sugar expanding packaging plant, investing US$4.3 mln.

Cane sugar refiner Redpath Sugar Ltd. is expanding its dry blending and packaging plant in Belleville, Ontario, to add new pouch packaging capabilities.

Exploiting CRISPR to increase crop yields.

Researchers at the Cold Spring Harbor Laboratory (CSHL) in New York provide a compelling demonstration of the power of gene editing to rapidly improve yield traits in crop breeding. Using tomato as an example, they have mobilized CRISPR/Cas9 technology to rapidly generate variants of the plant that display a broad continuum of three separate, agriculturally important traits: fruit size, branching architecture and overall plant shape.

Pakistan – Government approves exports of 500,000 t sugar.

The Economic Coordination Committee (ECC) of the Cabinet on 14th September allowed sugar mills to export 0.5 million tonnes of sugar, according to local press reports. No indication was given that the exports will be subsidized.

USA – Sugar industry in Florida assess damage from hurricane Irma.

Officials from the Florida State Department of Agriculture and Ryan Weston, CEO of the Florida Sugar Cane League, stressed that preliminary damage assessments are not yet available as the full extent of the damage to fields is still being evaluated. Flooded fields are hampering inspection of the cane crop.

Sugar shares in focus on import duty hike; Dwarikesh Sugar hits record high.

Shares of sugar companies were trading higher by up to 5% on the BSE on expectation of favourable outlook in FY2018, supported by the recent hike in import duty and a tight domestic stock situation. Dwarikesh Sugar Industries, Uttam Sugar Mills, Avadh Sugar, Dhampur Sugar Mills, Simbhaoli Sugar and Thiru Arooran Sugars were in range of 4% to 5% on BSE.

Sugar rush for Shree Renuka as Wilmar pumps in additonal funds to reduce debt.

Mumbai headquartered Shree Renuka Sugars announced an additional investment by Singapore based agribusiness giant Wilmar International of around Rs 784 crore along with an all-inclusive debt restructuring package on Friday. ET NOW was the first to report the deal talks on July 25th, 2017.

Long rain brings relief to sugar sector.

The continuous rain since last week has provided relief to sugarcane cultivators and sugar mills. The long dry spell in the first half of July could have had a long term impact on total sugar output.

Sugar mill gate prices fall on steady supply, low demand.

Sugar mill gate prices eased by up to Rs 15 per quintal at the wholesale market in the national capital today due to ample stocks following sustained supplies from mills amid scattered offtake. Marketmen said stock surplus following regular supplies from mills amid reduced offtake by stockists and bulk consumers such as soft-drink.

Sugar stocks spurt on spike in sugar prices on the NCDEX.

Nine sugar stocks surged 1.61% to 8.4% at 12:47 ISTon BSE, reacting to a spike in sugar prices on the NCDEX, where it got locked in upper circuit. Meanwhile, the S&P BSE Sensex was down 59.43 points or 0.19% at 31,895.92. Triveni Engineering & Industries (up 8.4%), Shree Renuka Sugars (up 7%).

Sugarcane crop is in the grip of boing disease.

जिला होशियारपुर में गन्ने की फसल पोका बोइंग रोग की चपेट में आ जाने के कारण गन्ने की काश्त करने वाले सैंकडों किसानों के चेहरों पर ङ्क्क्षचता की लकीरें दिखने लगी हैं। यह बीमारी गन्ने के ऊपरी हिस्से, विशेषत: नए निकल रिे पत्तो को जकड रही है।

Spot sugar price jumps to three-month high of Rs 4,050 a quintal.

Spot sugar prices rebounded sharply from a recent low to hit the highest in three months, following a global move and traders returning to the market after almost three weeks. The benchmark M-30 variety at the Vashi wholesale market jumped to trade at Rs 4,050 a quintal on Thursday.

Sugarcane farmers call off morcha.